This is one of the top questions we get asked.

First, let’s take the opportunity to explain what a Ground Heat Exchanger is:

What is a Ground Heat Exchanger?

The Ground Heat Exchanger is the component in the geoexchange system that extracts the heat from the ground in winter or returns it to the ground in summer. It is the passive component of a geoexchange system and is classified as either open or closed loop depending on how it utilises the water flowing through the system.

Closed loops are constructed of polyethylene (PE) pipe and continuously circulate the same water for many decades. They can be either a vertical (borehole) or a horizontal (trench) configuration and some are even located in surface water bodies such as dams and harbours.

Open loops use water directly from a water bore or surface water body for the heat exchange process.

This simple act of passively circulating water through the ground heat exchanger can provide up to 80% of the heat delivered into your home in winter. Regardless of the type of ground heat exchanger, it will be connected to a ground source heat pump (or geothermal heat pump), which is the mechanical component that delivers the heating or cooling into your home as per your thermostat settings. If you would like to learn more about ground source heat pumps, click here.

What is the best Ground Heat Exchanger for me?

Explaining the concept of a Ground Heat Exchanger is straightforward. However, it is a more complex process to determine the optimal Ground Heat Exchanger for homes and businesses.

This tends to lead to the following questions as homeowners begin their journey on the geoexchange path:

- ‘What is the best ground heat exchanger for my home?’

- ‘What sort of ground heat exchangers do we use?’; or

- ‘What do we recommend for their project?’

The simple response is that we design and install the best ground heat exchanger for the project. In most instances, ‘best’ means the lowest cost heat exchanger. Although there are occasions where this isn’t always the case and may not be the most desirable.

Types of Ground Heat Exchanger

Let’s start by considering the various types of ground heat exchanger or loop available and a brief description of each.

- Closed vertical loop (borehole):

WaterFurnace illustration of vertical loop for geothermal

A closed vertical loop requires a drill rig and is installed from depths of 50 to 150 m. It is typically the higher cost option and is required in most metropolitan or suburban lots due to limitations on land area.

- Closed horizontal loop (trenches or pits):

WaterFurnace illustration of horizontal loop for geothermal

A closed horizontal loop requires greater land area and sufficiently deep soil to obtain the target depth of 1.5 m. A minimum land area of 2 acres or 8000 sqm is a good area to work with as the trench will be several hundred metres long.

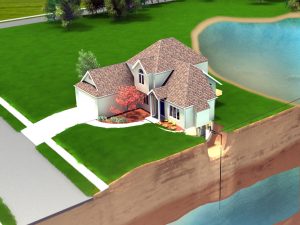

- Closed water loop (surface water body):

WaterFurnace illustration of pond loop for geothermal

A closed water loop requires a good sized dam / lake / harbour front with reliable depth and water volumes during drought periods and tidal variations.

- Open water loop (surface water body or groundwater):

WaterFurnace illustration of open loop for geothermal

An open water loop includes surface water bodies such as dams and rivers as well as water bores. Note that water quality and drought proofing are critical for these options.

- Energy piles (building piles or foundations):

Building foundations can provide opportunity for heat exchange in commercial buildings. However, this is typically a partial load and not a complete solution.

- Sewer heat recovery (could include treated effluent):

Yes, really. Believe it or not but it is possible to use sewer and grey water as a heat exchanger. However, it does require minimum flows so commercial or infrastructure scale systems only.

Not all of these are ‘ground’ per se, although the phrase ground heat exchanger is still regularly used. For the purposes of this post, we will discard the specialist options of energy piles and sewer heat recovery.

Factors in establishing an optimal Ground Heat Exchanger

So what do we consider when assessing the optimal system for a specific project? The considerations include:

- Capital cost

- System efficiency

- Available land

- Available water bodies

- 20 year system performance, both technical and financial

- Future land use

- Future changes to the building / home

- Changing climate / weather patterns

- Future energy costs

- Future energy sources

A typical assessment of the best ground heat exchanger starts with asking questions of the building size and the size of the land area available. There are a few rules and patterns but as with most things, there are always a few exceptions.

Due to the smaller land area, suburban lots require the vertical systems of either closed vertical or open water (groundwater). The open water systems are only an option in areas where good groundwater is available, which rules out most suburban areas in Australia. A notable exception is Perth, where open water loops are a plausible option due to the abundance of groundwater in a significant portion of the metropolitan area.

The other exception is closed water loops on water front properties such as harbours, rivers, canals etc where access to the water body is achievable through a jetty or pontoon like structure.

In rural areas, where land or dams are present, closed horizontal loops and closed water loops are an option.

With respect to overall system efficiency, we expect similar high efficiency from whatever system is selected. Any efficiency differences are highlighted to the Client during the design process, as are of course, the pros and cons for each system for that specific site.

…and that is the key to a successful geoexchange system… a ground heat exchanger that is designed and installed to best fit that specific application. There is no such thing as one size fits all when it comes to ground heat exchangers.

Our designers and installers are trained to ensure you receive the best fit for your home.

Contact us today to find out what is the best ground heat exchanger for you and your home.